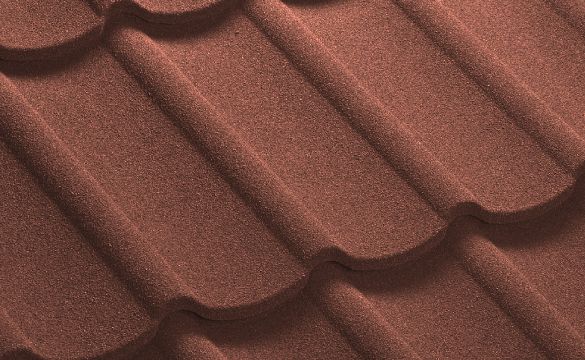

DECRA ROOFING SYSTEMS TRUSTED MORE THAN ANY OTHER ROOF BRAND IN AFRICA

Over 25 million square metres of Decra® keeping African families safe

OUR DECRA® TILES

OUR DECRA® FORTIZA® TILES

EXPLORE DECRA® ROOFS

HISTORY AND HERITAGE

Discover how the Decra tile was invented and how we have led the world for over 60 years.

Beware of fake Decra tiles, they will not perform to our high standards. Find out how to tell the difference & achieve the highest value for money.

Find out how a Decra Roof Tile is made and why our tiles outperform all other metal roofing.

Whether it’s wind, rain or fire, Decra Roof tiles lead the world in performance and also comes with 50 years warranty.

NEXT STEPS

We’re here to guide you through the process of selecting the right roof for you.

Our Distributors are professionals who will listen to your requirements, make recommendations and calculate your roofing needs, For your dream roof, make an appointment on a day and at a time that suits you…..